Products

METALLIC MAG-DRIVE REGENERATIVE TURBINE PUMPS

Main Features

Mag drive regenerative turbine pumps series MGTSS are made of AISI 316 or, if requested, of other metallic materials (HASTELLOY or TITANIUM) and are suitable for solvents, hydrocarbons, dangerous and inflammable liquids. Thanks to the innovative mag drive system, pumps model MGTSS reduce the risks of leakage and emissions and maintenance costs. The transmission of the motion occurs through magnetic joints without any mechanical seal. This design guarantees the maximum hermetic safety and efficiency. The pumped liquid has to be clean and without solids in suspension. Pumps series MGT-SS are also available in ATEX version for zone 1 and 2 (pump model EM-T).

• High head / low flow capability minimizes by-pass requirements.

• Materials available: AISI 316;

• Materials in contact with the liquid:

Casing and impeller: stainless steel AISI 316;

O-ring EPDM/VITON;

Bushing: PTFEC; shaft: Hastelloy C276.

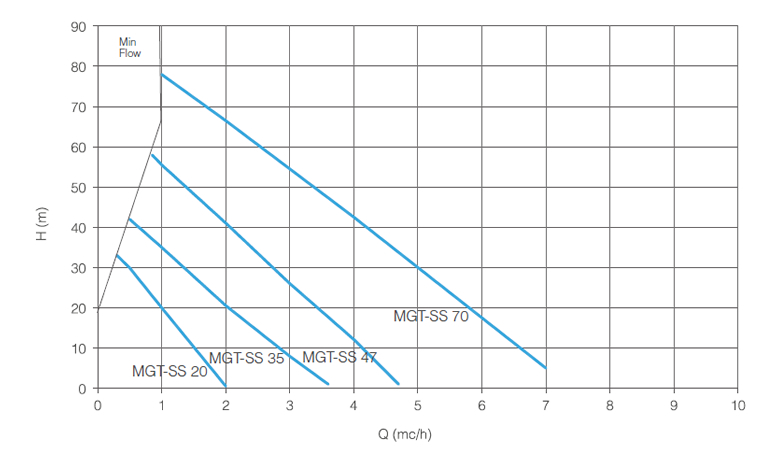

• Max flow 7 m3/h; max head 80 mlc.

• Max Temperature: 160° C.

• Pressure Rating NP 25 at 20° C.

• Impeller design handles up to 20% entrained gas.

• Ideal for pumping liquefied gas.

Standard:

• Static shaft in HC 276.

• Chemical resistant PTFE/Carbon sleeve bearings standard.

• High torque magnetic coupling.

• Direct starting motors.

Optional:

• ANSI 300 flanges available.

• Atex version.

• Explosion proof motor.

• Dry-running protection.

• Baseplate.

Performance Curves 50 Hz – 2900 RPM